Effect of speed on printing time

May 8, 2021, 1:17 p.m.Just after writing the previous article about the advantages and disadvantages of the Creality Ender 6 printer, information about another novelty from this Chinese company came out. She brought another printer to the market with serial number 7.

*Ender 7 source: https://www.creality.com/goods-detail/creality-ender-7-3d-printer*

The Ender 7 primarily boasts a new design and a very high print speed of up to 250 mm/s. This is possible thanks to the Core XY technology, which is described in the last article about Ender 6 and last but not least thanks to the Linear guidance in the X and Y axes. The cooling of the print is taken care of by a pair of radial fans 4010, which should bring 69% better cooling than the single fan variant. The printing area is 250 x 250 x 300 mm and the price is set at 699 dollars, which is a little over 16,000.

The question remains whether the printer will once again confirm Creality’s claims and really be able to print at a speed of 250 mm/s. If so, it would mean that compared to standard printers with a speed of up to 100 mm/s, it would be 2x faster, which is a significant time saving, especially for larger prints. The main improvement of the printer over the previous generation is the movement on a linear guide, which allows the printer to increase speed while maintaining printing accuracy. However, these high speeds are not so much about the maximum possible speed, but also about acceleration. The default acceleration is 500mm/s2 and I don’t think there will be a number for this printer. If we wanted to use these or similar speeds for smaller models, we would have to go to thousands of mm/s2, which is precisely what a linear feed would allow better.

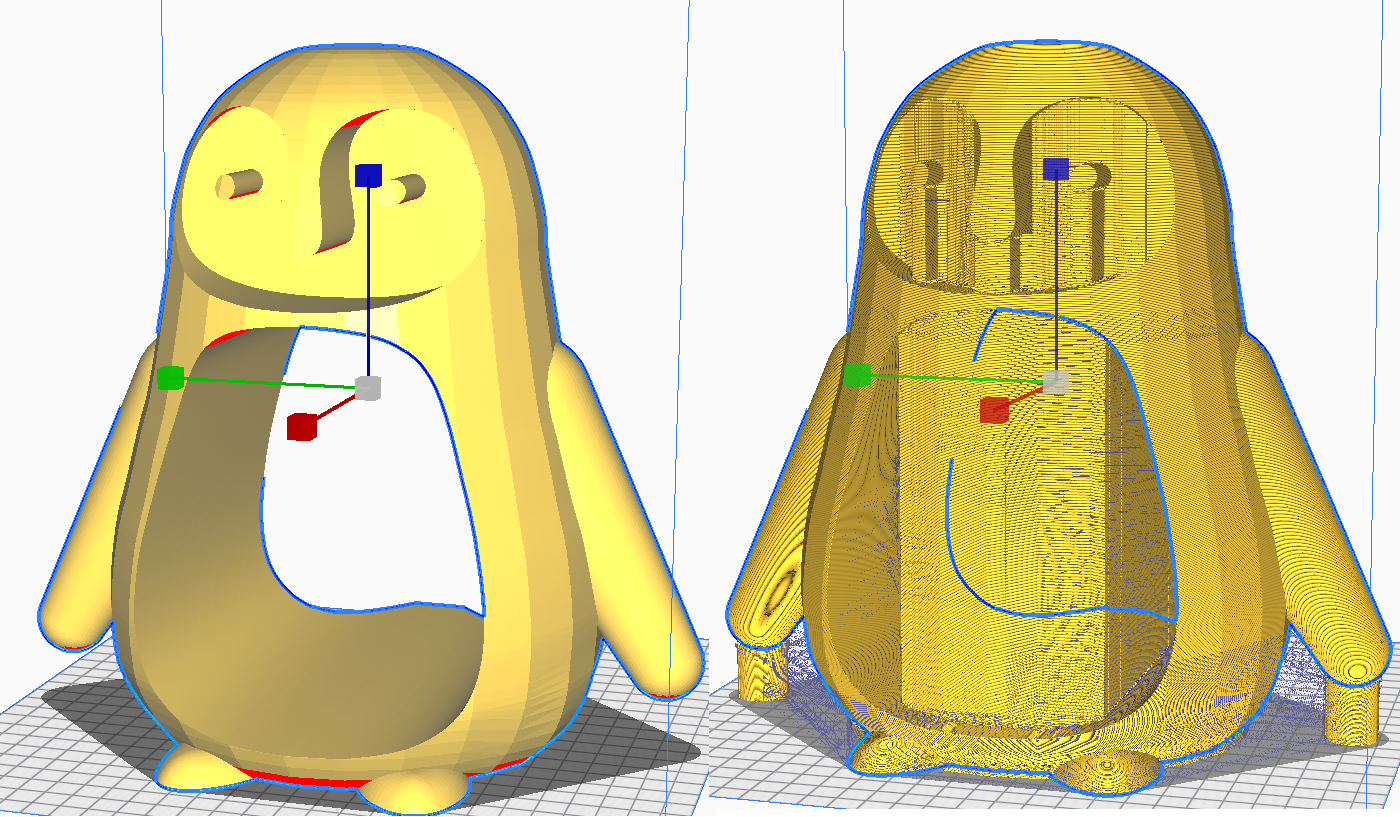

For an idea, I turned on Slicer Cura (version 4.10.0) and was wondering how the print times would adjust when changing speeds. I came across a penguin model and sized it up so that it uses 997g of filament including the supports, which is equivalent to one standard package.

Penguin model before and after carving

I used the Standard Quality profile for the Ender 5 printer, with a layer height of 0.2 mm. The only change is removing the Build Plate Adhesion Plate and adding supports to the default settings.

Cura only uses the default print speed for fills. Divide other speeds by two. I decided to leave the default speed even for printing the inner walls. The set speeds for individual printers are in the table.

I left the first layer’s passes and speed the same, even though it’s clear that the Ender 7 will be capable of 250mm/s passes. I also left the acceleration at the original value of 500 mm/s2

From the times calculated by Cura, it is evident that the printing time of such a large model will vary greatly on individual printers. According to my calculations, the Ender 6 Printer with such settings is 18.7% faster than the Ender 5. The Ender 7 is even 32.7% faster than the Ender 5. Comparing the Ender 7 and Ender 6 printers, there is a 17.2 print speedup %, which means it’s a similar generational jump in time savings as between Ender 5 and Ender 6.

As for the accuracy of this calculation, it must be taken with a large margin. Although Cura estimates the print time with my Ender 6 very accurately, down to the minute, there are a few unknowns.

First of all, Cura does not like print speeds above 150 mm/s and tints them orange. I don’t know how it responds to that by calculating the print time itself, but the accuracy may vary.

Another important thing is the aforementioned acceleration. I didn’t even try to include it in the calculation, because Slicery doesn’t know how to work with it, and it’s actually logical. I tried changing the acceleration on the Ender 7 from 500mm/s2 to 2000mm/s2 and the difference was about 18 minutes. Personally, I think it will actually be more, because when I tried to change the acceleration on my Ender 6, it was more noticeable even with the eye and I was moving at speeds of around 120 mm/s.

In conclusion, I would like to say that the shift in declared speeds for the new Ender 7 model did not surprise me, but rather I like the direction in which 3D printers are developing. It can be seen that manufacturers focus on what customers subsequently do with their printers and try to adapt them to these requirements. Specifically, I mean better printout and linear guidance. Personally, I like the Ender 6 better despite all this, but the linear guidance would be very useful with the Core XY combination. The Ender 7 certainly has certain shortcomings, such as the massive construction in the upper part of the printer, which prevents access to the printing pad and others. First of all, I hope that Creality learned from the previous Ender 6 and the firmware on Ender 7 will be better