Ender 6

April 13, 2021, 1:21 p.m.For 2021, the Chinese company Creality has prepared several novelties in the field of 3D printing. One of them is the innovative printer Ender 6. The printer offers a printing area of 250x250 mm (actually up to 260x260 mm) and a printing height of 400 mm. The printer itself has dimensions of 495x495x650 mm and weighs a respectable 25 kg.

Creality Ender 6 (source https://www.crealitystore.cz/p/creality-ender-6)

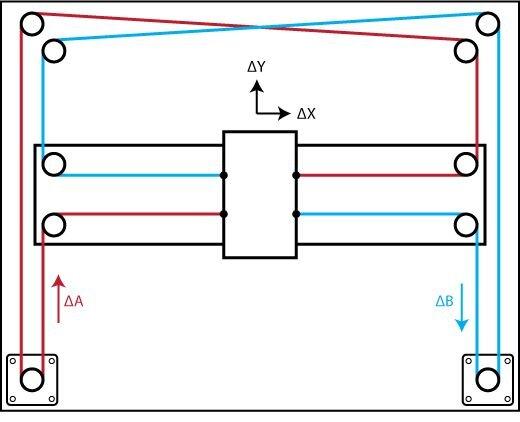

But the Ender 6 is interesting mainly for its printing speed. Creality claims a speed of up to 150mm/s while maintaining an accuracy of ±0.1mm. Most printer manufacturers, including Creality, state the speed as the maximum possible, but this is usually not realistically usable. But with the Ender 6, a speed of 150 mm/s is realistic while maintaining a reasonable print quality. Higher speeds are achieved with the Core XY movement mechanism. This technology has already appeared on printers from other manufacturers, but it is completely new for Creality. The movement is made up of straps that are tensioned by a system of pulleys, as seen in the picture. Movement purely in the X or Y axis is therefore not made by one motor, as is the case with classic printers, but by both motors (X and Y). Rotating both motors in the same direction results in horizontal movement. Rotating both motors in opposite directions results in vertical movement. Both motors are firmly attached to the frame of the printer, not to the print head, which significantly reduces inertia and thus increases the quality of printing even at higher speeds.

*Figure 2 – Classic/Nonplanar print source:

At first glance, you can see that the Ender 6 is partially covered, which brings all kinds of advantages. It may seem that the cover makes it possible to better print larger objects from materials with high shrinkage, such as typically ABS. Unfortunately, this is not entirely true, because only the sides are covered, but not the top of the printer. This means that most of the heat will escape through the top of the printer. Certainly more heat is retained in the printer than in a completely exposed one. So you may be wondering what the sidebars are good for. In practice, it serves well as protection against drafts. Typically if you walk around the printer, opening the door, this can have a negative effect on the final print quality. Another advantage of covering is the slight noise reduction of the printer. It doesn’t seem like it, but even partial coverage against noise helps. After all, the noise does not spread so much to the entire surroundings, but it is clear that most of the noise leaves through the top. The biggest noise on the entire printer is caused by the hotend blowing, which is anyway on top of the printer.

My short assessment:

I’ve had the printer for less than a week, so I haven’t tried everything, but I’ve already managed to form an opinion.

Overall, the printer met my expectations. Its composition is very simple and fast, the instructions are clear. After assembling the printer, there is no need to adjust anything, the main components are already assembled, I started the print and it went fine.

As far as covering is concerned, it is definitely recommended to finish the top cover for the printer. This would also solve the fairly large noise of the hotend. I definitely plan on going full coverage, so you can look forward to me showing you the solution in one of the next articles.

Lukáš Židek