Is 3D printing really 3D?

Oct. 14, 2021, 1:37 p.m.I’m probably not the only one who has wondered if the ubiquitous 3D printing is really 3D. When you think about the function of classic FFF printers, you will probably realize that it is not a full-fledged printing in three axes. What i mean? Simply put, the X and Y axes can move at the same time by default, so they perform 2D movement and thus create individual layers. By default, the Z-axis only moves when the entire layer is finished and the next layer can be printed. It follows that not all axes move at the same time, i.e. they can move at the same time, but no printing is done during this movement. In addition, we are limited in the Z axis to only move in one direction.

Someone may argue that when using the Z-hop function, the Z-axis also moves during the printing of one layer. This is true, but when the Z-axis jumps up and then goes down again, printing does not occur, but on the contrary, it is used when the printer does not want have filament defects visible on the print surface. (How does Z-hop work? Let’s imagine that the printer finishes printing one part of the print and wants to move to the next part. The printhead moves up a bit so that the excess pressurized filament from the nozzle is forced upwards behind the movement of the nozzle and not to the sides as it passes. it partially avoids the ugly surface in the places of crossings, but it slows down the printing a bit and can affect the next layer in the places where the Z-hop was performed on the previous layer).

Another special function that, in my opinion, is closest to real 3D printing is Vase mode. This mode works in such a way that the entire printout, except for the bottom layers, which can be printed as standard, is printed as “one” layer. How is it possible? If we imagine printing a hollow cylinder, which will have a wall thickness equal to the width of the print extrusion, we can print it simply by one embrace of the given circumference. The principle of your mod is the smooth connection of individual layers. In other words, the print head moves in the Z-axis so that after one layer is printed, it is at the height of the beginning of the next layer. Thus, the shift in the Z axis occurs smoothly during printing in the XY plane. The entire print is therefore made up of one spaghetti, which flows smoothly into each other. A cylinder printed in this way, or an object in general, will not have a seam, which is a great advantage. Another advantage is faster printing because there is no slowing down and speeding up of the print head when changing layers and we don’t need to use any retractions. Another advantage is linked to this, which is the maintenance of a constant flow of material and thus easy regulation of the printing temperature, which is very important for some materials. But a big disadvantage is the limited use. Obviously, only certain types of models can be printed in this way. When designing a 3D model, it is worth considering whether it could be made so that it could be printed on Vase mode.

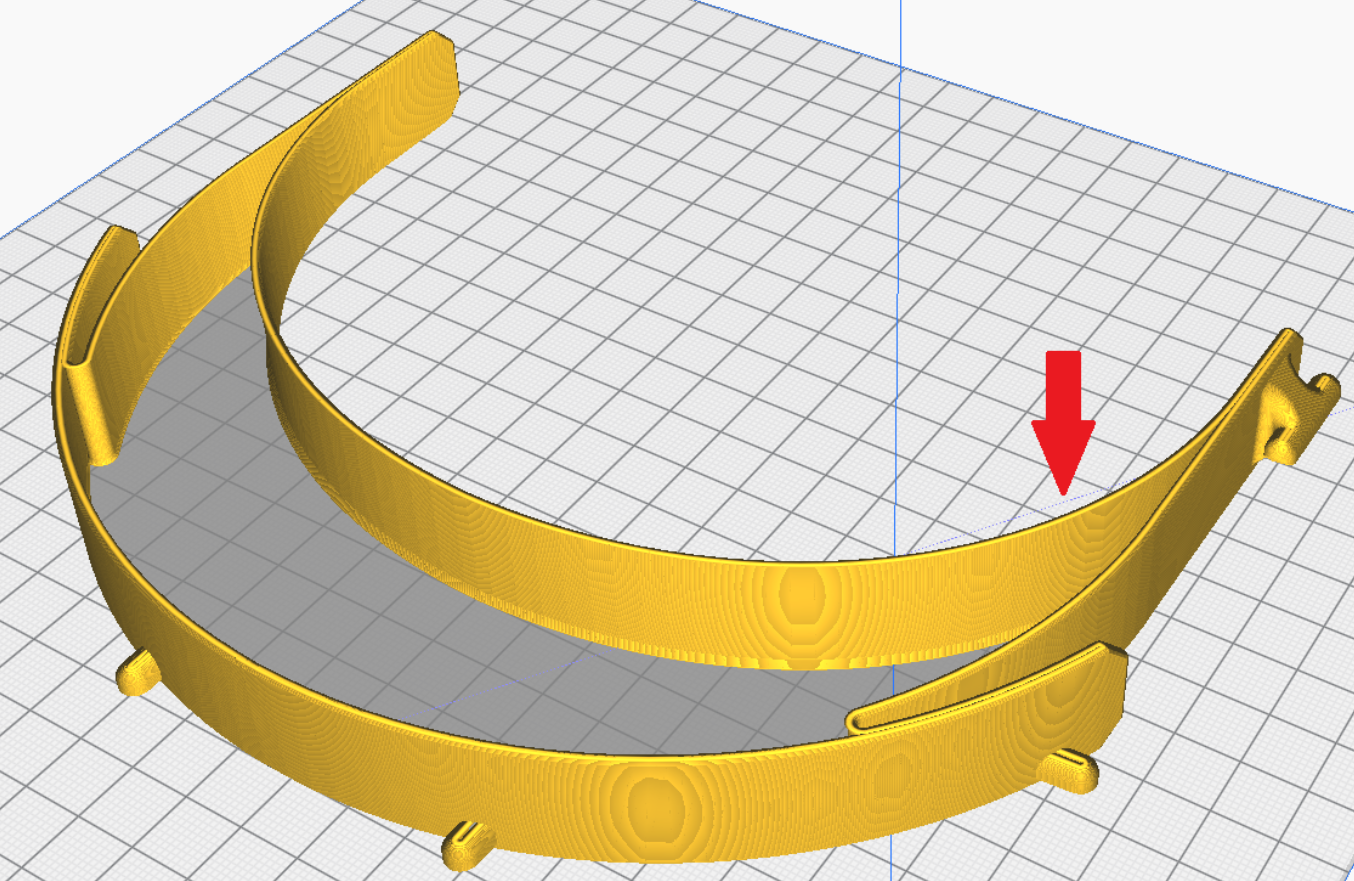

At the beginning of the Covid pandemic, the 3D printing community united and started to print headbands on shields for medical workers on a large scale, in which some companies also joined. A similar 3D model of the headband, which was expanded by Prusa Research, was modified by someone in the community so that it could be printed on Vase mode, which significantly simplified and accelerated printing. It is a relatively complex shape, but it was possible by modifying the model. To ensure the strength of the shield, it was necessary to print the model with 1 mm extrusion and ideally to have an increased Flow to 120%. When the headband was printed correctly it worked great, but unfortunately a lot of people were rushing for time and the quality wasn’t good at all. Unfortunately, these headbands could not be used because they were not strong enough. Figure 1 shows the rendered headband in Vase mode in the Cura software. The visibility of crossings is turned on in the preview, but there is only one on the entire print, and that is the one on the first layer. I was very interested then, and that is why I am very interested in your mod and use it as much as possible.

Image 1 - Personalized headband printable on Vasemode - Cura

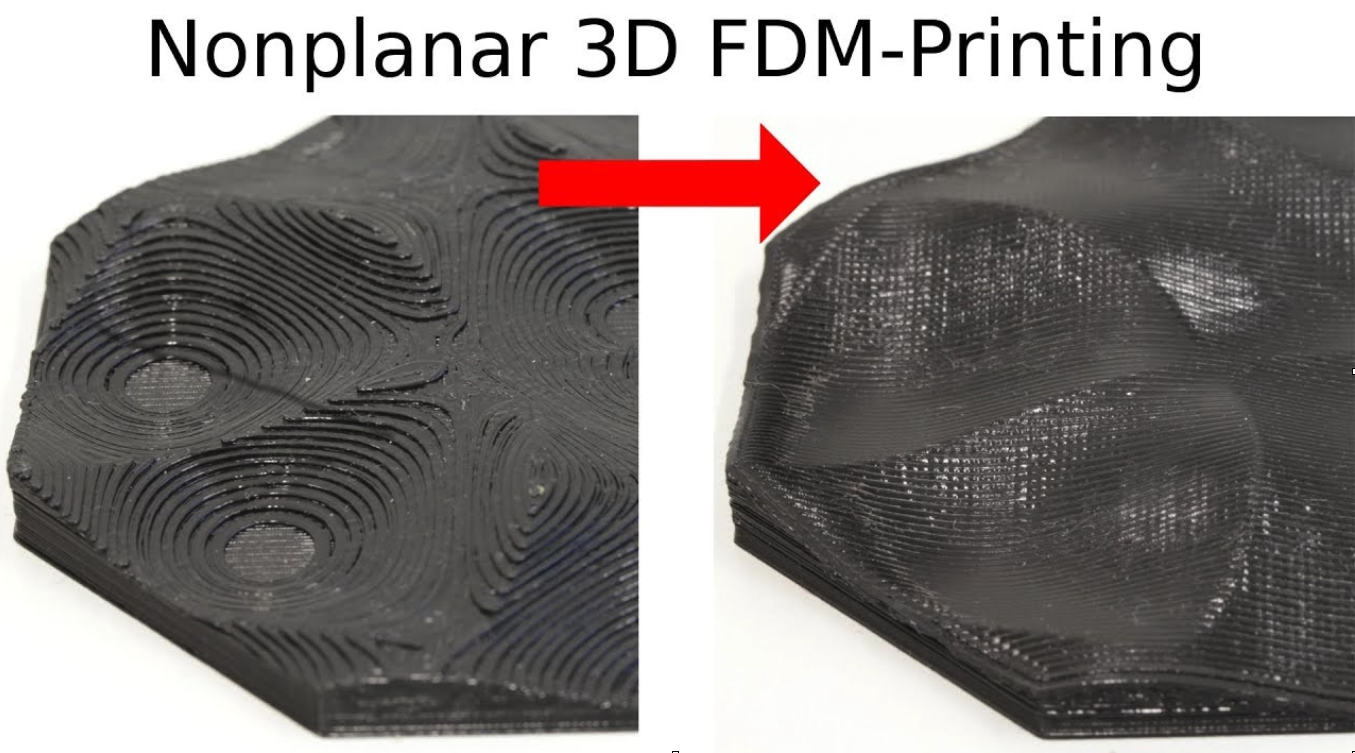

This probably exhausts the possibilities of classic FFF printing. But there are certain experimental methods that push FFF 3D printing even further. Specifically, I mean Nonplanar printing. We explained above that during standard printing one layer is printed in one plane (Planar printing). It follows that non-planar (Nonplanar) printing does not stay in one plane, but makes limited use of the entire 3D space. Printing works in such a way that during the printing of one layer, the printer can move the Z axis while maintaining movement in the X and Y axes. So, if we wanted to print a hill in the shape of Mount Říp, we can print the basic shape with classic Planar printing and then “print” a pair of TOPs on this shape layers Nonplanar printing, which would cover the imperfections of standard printing. Figure 2 shows classic planar printing on the left and nonplanar printing on the right. Another use is the printing of more complex shapes, such as various propellers, ship propellers, airplane wings and the like.

*Figure 2 – Classic/Nonplanar print source:

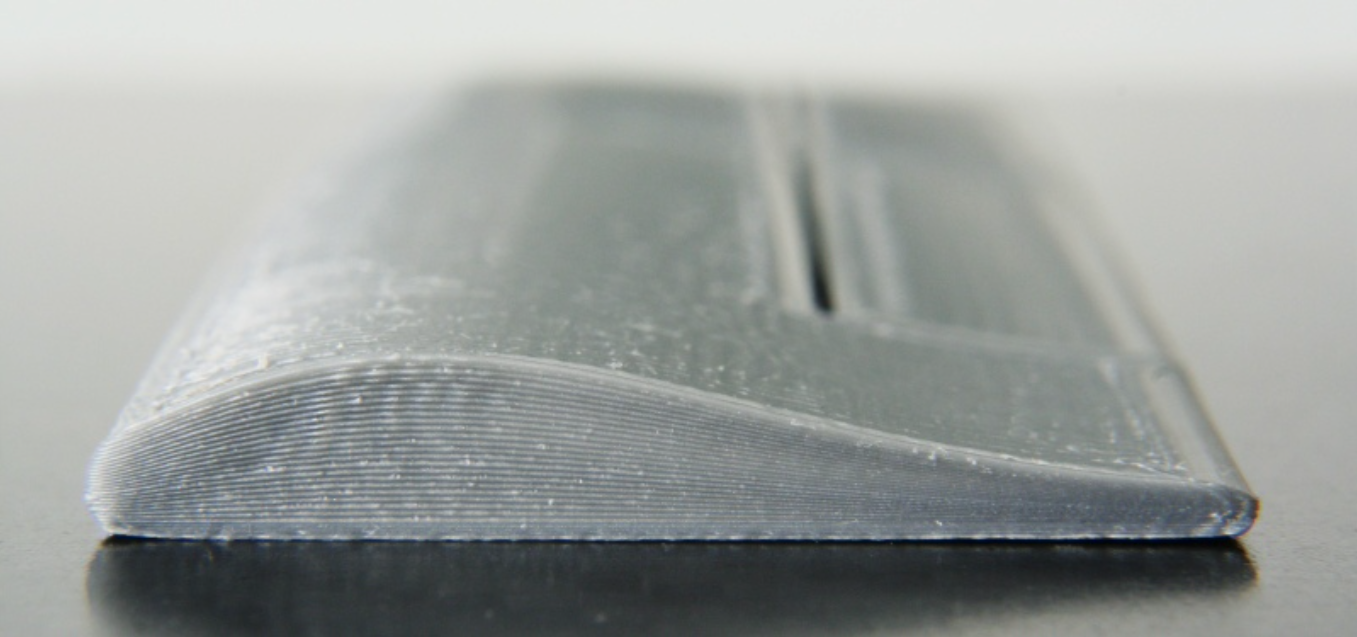

On the Internet you can find many videos and articles in which you can see the results and also compare the prints of both methods. Picture 3 shows a side view of an airplane wing that was printed using the Nonplanar method.

*Figure 3 - Example of Non-Planar Printing Source: https://hackaday.com/2016/07/27/3d-printering-non-planar-layer-fdm/*

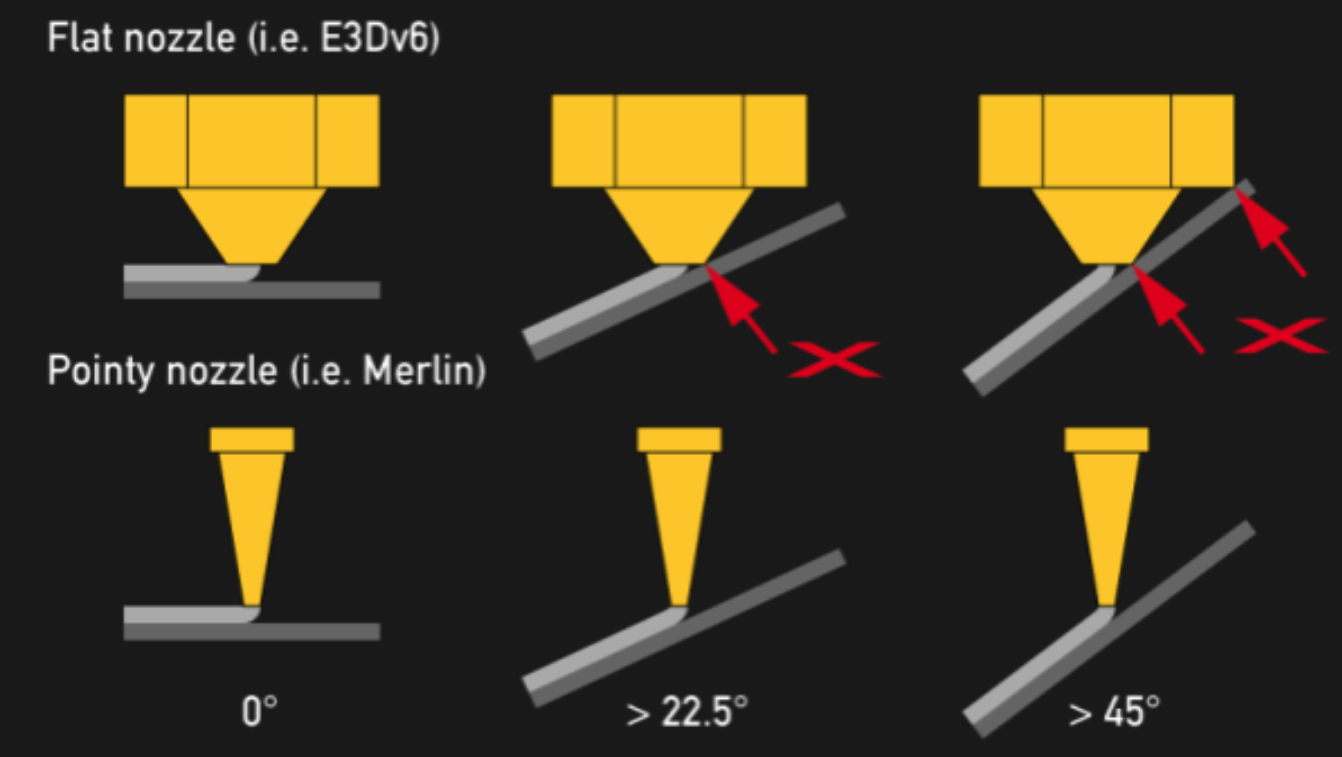

Interestingly, such printing can be achieved even without major physical modifications to the printer, but this results in certain limitations. First of all, the software must be adapted, both on the part of the printer firmware and the slicer. In the second row, there is a limitation on the side of the print head. Figure 4 shows the problem that occurs with Nonplanar printing. In the left part of the picture we see the standard Planar print that we are all familiar with. The middle and right part of the picture show the different angles at which classic nozzles can and cannot print. Assuming that we do not adjust the print head or the nozzle on the printer, it is possible to achieve lower angles than if some more suitable solution is used, such as longer nozzles, etc.

*Figure 4 - print angle limitations source: https://hackaday.com/2016/07/27/3d-printering-non-planar-layer-fdm/*

Another option is to start adjusting the print head. If two more degrees of freedom were added to it, it would be able to tilt in two axes and thus it would be possible to print at a larger angle, but we could call it 5D printing (Possibly 3+2D printing). However, with such a press, we would certainly encounter a lot of problems in various areas, and it is a big question whether something like this is needed at all.

To finally answer my question from the beginning of the article, are 3D printers really 3D? It is clear that they are, mainly due to the fact that they will create a 3D object exactly according to our template. By default, however, we are limited to print growth in one direction of the Z axis, and that is often enough for us. Where it is not enough for us, we simply use support or divide the printout into several parts.

However, I personally think that the future of multi-axis machines awaits us, which will be able to provide full-fledged three-axis or multi-axis movement with the help of various robotic arms. But the question is whether there will be sufficient application for them.

After all, if you need a multi-axis 3D printer, buy a 3D pen… 😊

Lukáš Židek