Karmen turns common 3D printers into smart ones

March 30, 2020, 1 p.m.A Czech developer company Fragaria introduces Karmen: a solution to make common 3D printers “smarter”, to improve their accessibility and to make their usage a lot more convenient.

Karmen users can manage their 3D print jobs from anywhere in the world—run them, pause them, cancel them or just merely watch their progress layer by layer. It doesn’t matter where the printer operator resides: being it in the same room, at work or on the other side of the globe. Up until now, printer operators had to be physically present at the very place where print happens as most printers simply lack the remote management support.

“3D printing or additive manufacturing isn’t just a lab high-tech business anymore, it gradually makes its way to schools, offices, engineer workshops and home hobbyists. Unfortunately, the majority of current printers force their users to stick around—they’re not connected to any network and have to be managed and controlled locally. When dealing with more demanding print jobs that require multiple hours to finish, this limitation turns out to be rather impractical. More often than one would like, this results in print jobs having to be repeated over and over from the beginning. Thanks to the Karmen cloud service and Karmen Pill controller, this problem becomes a thing of the past,” says Martin Burián, Fragaria’s chief executive.

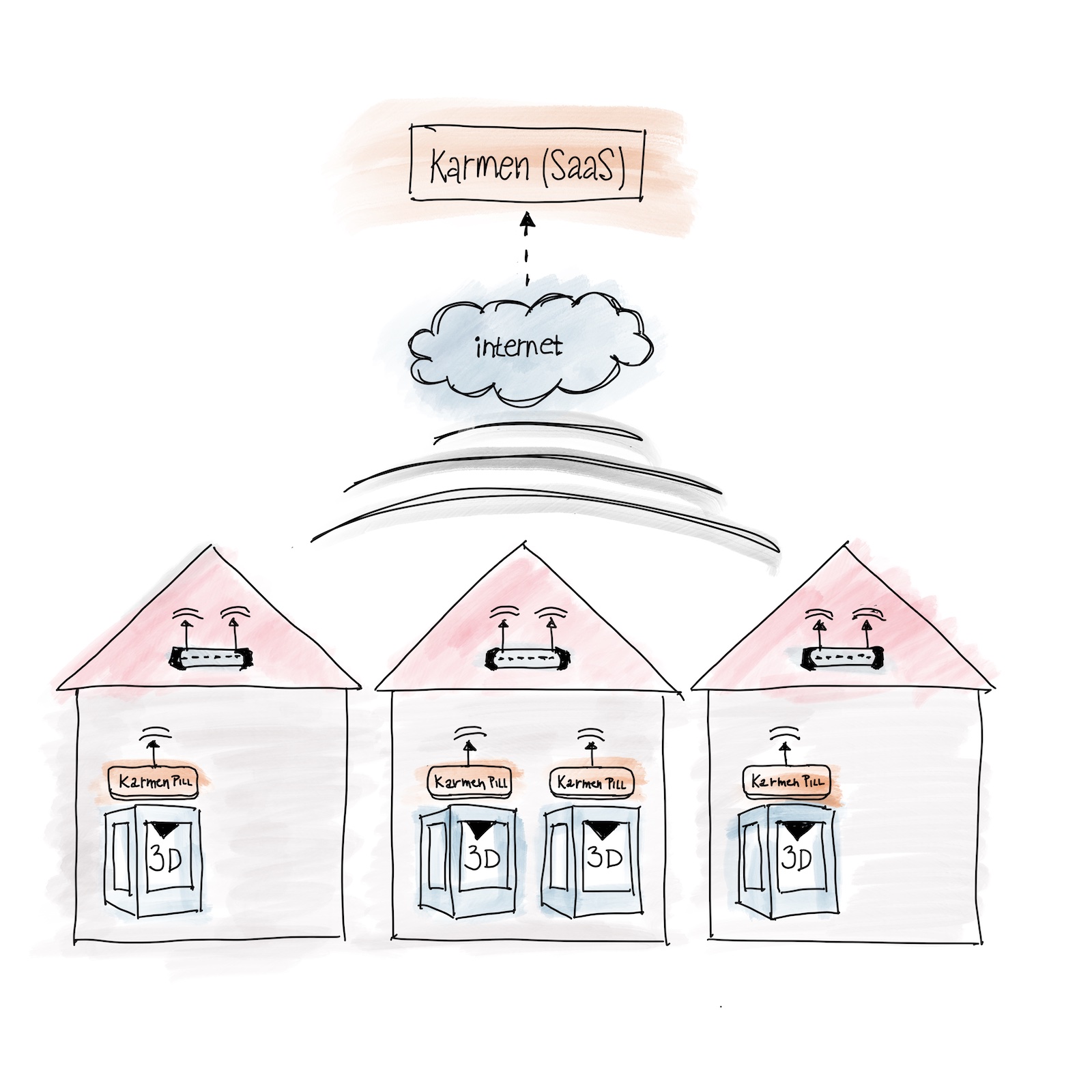

The Karmen solution stands on two pillars: a cloud service called simply Karmen and a unique hardware controller named Karmen Pill.

The cloud service is being developed as an open source solution and its task is to control an arbitrary number of 3D printers directly from a web browser running on one’s computer, tablet or smartphone. It can be used to schedule print jobs, inspect print progress or distribute jobs among printers. Thanks to the software solution used it is compatible with a broad range of printers and slicers.

Karmen cloud service supports most of today’s smart printers equipped with additional hardware like Wi-Fi network adapter, webcam for printer monitoring, assistive lighting or some diagnostic facilities. That said, most current FDM 3D printers still don't support it and that’s why the Karmen Pill controller is available for purchase to fill in the gap.

Karmen Pill is a tiny box (measuring only 77 x 34 x 12 mm) that enables you to connect your printer to the local network or to the internet, and to link it up with the Karmen cloud service. Printer connection is made using an USB interface.

It is compatible with the most widely used slicers including Slic3r, PrusaSlicer and Ultimaker Cura. Besides the live video streaming capabilities, it provides its users with real time diagnostics like temperature sensor details and ongoing print stats. Likewise, basic printer controls—the start-stop-pause combo—are also available. It is based upon an open source Octoprint printer controller.

The Pill is priced at 130 EUR excl. VAT, pre-orders are already available on karmen.tech website. If you decide to go with our hosted cloud service option, you will be granted limited traffic and printer connections for free.

“Whole Karmen project is designed to be mostly open source. We are huge open source supporters and have strong confidence it is the right way to go. Our goal is to create a thriving community of developers and home hobby enthusiasts that will help us improve the project further. Nevertheless, for those who want a production-ready, fully supported and regularly updated solution to just connect their printers and manage them remotely without a hassle, our paid cloud service with the ready-made Karmen Pill controller is available,” adds Martin Bílek, Fragaria’s CTO.

During the testing period which took several months, Karmen has been battle-tested by selected clients from the ranks of individuals, companies and even big corporations. Some of the happy users include IKEM, Třebešín Technical College, an innovative medical equipment producer BTL, Czech Technical University in Prague and several other schools and makerspaces.