PLAsteosaurus

Aug. 1, 2022, 2:17 p.m.The PLA(S)TEOSAURUS project was created not only for dinosaur lovers, but it aims to educate people about climate change and its impact on all of us. This is a cooperative printing project of a huge Plateosaurus, in which any 3D printer owner can participate.

On the https://petmat.cz/plasteosaurus page, just select the Plateosaurus part. Subsequently, its 3D model will be sent to your email. After an agreement with the non-profit organization PETMAT z. ú, which is in charge of the entire project, they will send you recycled filament from which you can print the selected part. You mark the printed part and send it back to them. You can choose more parts, but from what I have noticed, they are always gone quickly after they are published. On the website you can even see who has already printed how many parts.

The assembled Plateosaurus will subsequently be unveiled on October 13, 2022 at the National Museum as part of the international Global Goals Summit, which deals with sustainability. The Plateosaurus itself will be on display at the museum as a temporary exhibit, so it will be possible to see it in its entirety when visiting the National Museum.

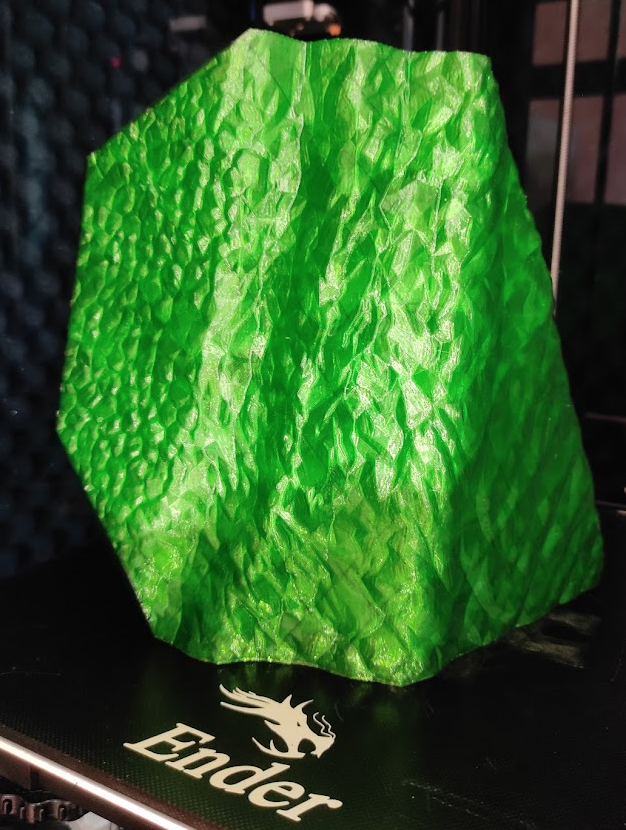

I personally came across the project by chance on Facebook 3D printers. I immediately unregistered, chose one of the larger parts, due to the large print surface of my Ender 6 printer. As I am from Prague, I agreed with the organizers that I would pick up the printing material in person in Prague. The material for printing is recycled PETG from the company EKO MB. I personally had no experience with rPET-G, so it was a bit of a challenge. Recommended print parameters are nozzle temperature 225-245 °C and substrate temperature 70-90 °C. At first I thought that the completely covered Ender 6 would be great for high temperature printing, but the first results of the prints did not convince me of that. I had the best results with the top cover open. Despite the fact that I am not in the habit of blowing much on classic PET-G, with this material it worked for me to have the blower on. After that I got to printing at 90/60mm/s very quickly. It was enough to heat the pad to 75°C, but I had to have the nozzle at 245°C due to the speed, 0.5mm extrusion and 0.25mm layer height. Estimated printing time with the Cura slicer was around 10 hours, which I thought was OK for the size of the model (117x214x201 mm). The printer with the Klipper firmware was able to reduce the real print time by almost an hour, which is a very nice result.

Figure 1 – Part One - Body Part

I am satisfied with the print result except for the seam, which is nothing extra. But I cleverly placed it inside the dinosaur, so no one can see it from the outside. In total, I used something between 300-350g of material for printing and tests, so I plan to print some more.

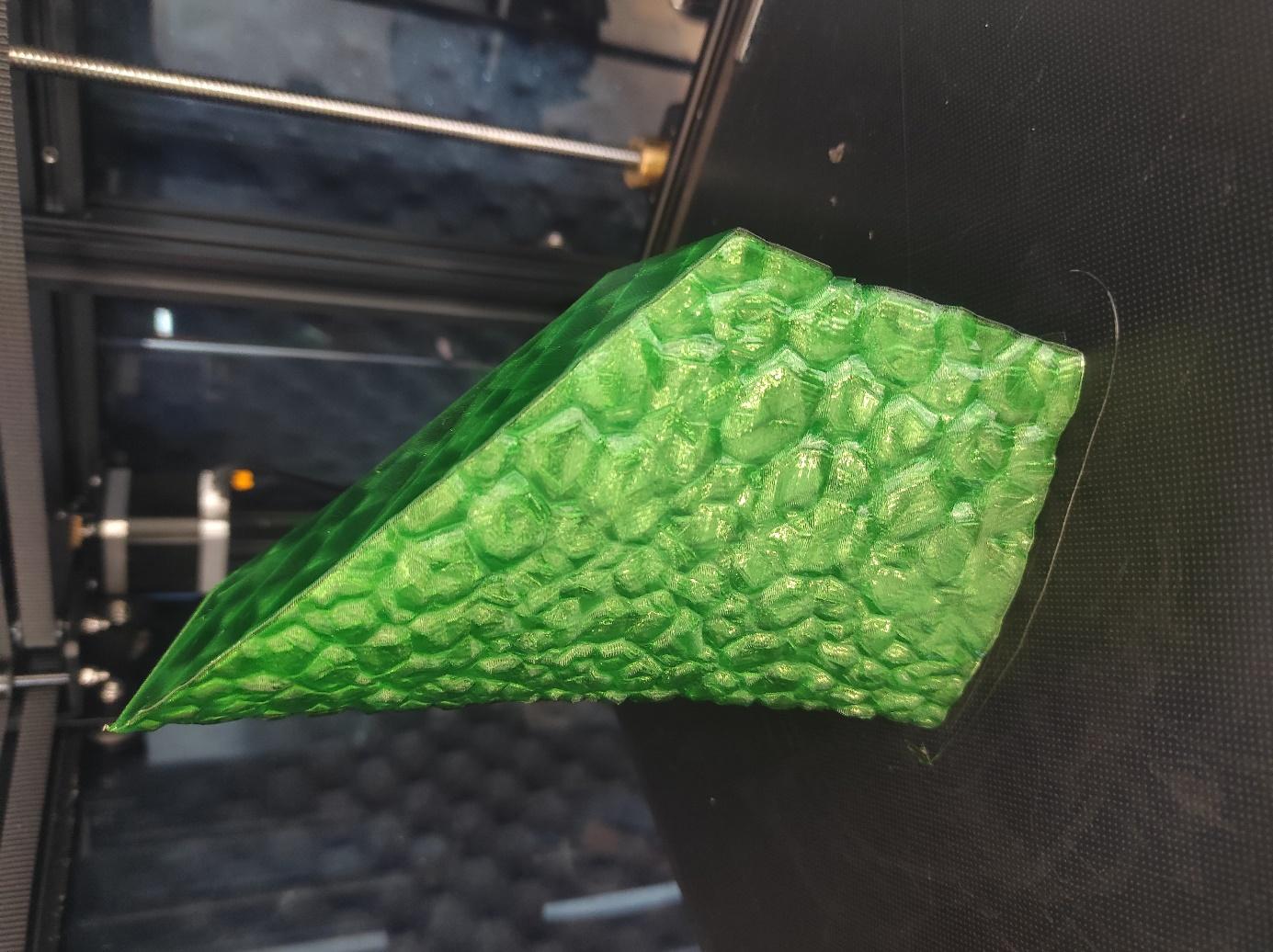

On Monday, July 4, 2022, I managed to capture another part of the dinosaur. This time, individual parts of the Plateosaurus neck were published. The models I was choosing between were significantly smaller than the previous model. I already had the print profile ready and the printing of the neck itself didn’t even take 3 hours. You can see the result in the second picture.

Image 2 – Part Two – Neck Part

As there is huge interest in the project, all published parts are taken apart very quickly. The last and as yet unpublished part of the Plateosaurus is the head. As I think the head is the most interesting part, parts will surely be reserved very quickly once it is published. In the recent third newsletter, the organizers also mentioned the great interest in the newly published works and hinted that they might come up with another interesting project for us printers in the future.